As promised, in this article we will look at anchor and belay systems in relation to mechanical advantage systems (MAS). We'll also explore how to simply figure out what a mechanical advantage system's value is by simply looking at it.

First, let's briefly review the three different types of MAS.

The first being the simple MAS. In these systems, all the moving pulleys move towards the anchor at the same speed. An example would be a simple 4:1 and a 4:1 block & tackle system.

The second type of MAS was a compound MAS. It is created by adding one simple system to another simple system on the input side. An example of a compound MAS would be a simple 4:1 MAS This is simply a 2:1 pulling another 2:1. If you recall from the last article, in compound MAS when we add one system to another we multiply the two system values together to obtain the new MA value. In the case of the example above 2:1 x 2:1 = 4:1.

The last system we'll review is the complex MAS. A complex MAS is created by combining a simple MAS with a compound MAS. Just like the compound MAS, the system value is calculated by multiplying the two system values together. Remember, regardless of which system you are building, you must pay close attention to the first number in the MAS (5:1). This will play a role in determining how much rope you will need to build your system.

In a 5:1 MAS for every five feet of rope pulled your load will move one foot. If you have a victim that needs to be hauled 20 feet you'll need 100 feet of rope just to achieve your 20-foot raise. In actuality, your rope length will be over one hundred feet leaving excess rope for hauling. So, with that said take the time to properly size-up your rescue and prevent yourself and your team from being left short when it counts.

Determining The System's Value

Now that we've had that brief review, let's dive into how to figure out what a system's value is. For us to be able to figure out a system value using the math mentioned above, we need to have the ability to pick a system apart and figure out what systems are actually there. How is this done? By simply looking at the system and visually organizing it. You'll find when working with ropes that the more organized you keep your systems the easier your rigging operation will go. That's something we'll talk about again later.

For now let's apply it to the topic of MAS. When calculating the value of a system you need to "read" the system, or in other words see what systems are there. First, start with the pulleys. Remember anchored pulleys provide no mechanical advantage, while traveling pulleys do.

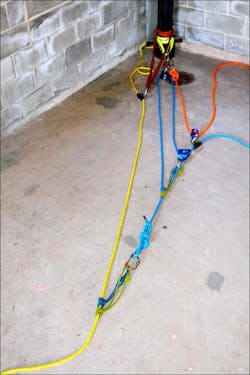

Let's look at Figure 1, it depicts a 3:1 MAS. Simply follow the rope through the pulleys. You should find a 2:1 and a 1:1. (2+1+3) Although a 1:1 provides no mechanical advantage it's still a simple system.

Let's take a complex 6:1 MAS. Take a moment and really look at Figure 2. What do you see? Follow the rope starting at the load end. You can clearly see a 3:1 MAS being pulled by a 2:1 MAS. However due to the self-defecting middle leg of this system the MA in actuality is 5:1.

Let's look at Figures 3 and 4. Both are 4:1 MAS; just different versions. Even though the systems were constructed differently if you look you can still pick out the two 2:1 MAS pulling each other. Let's look at Figure 5; take a moment and break the system down. What do you see? You should see a 2:1 pulling a 3:1 equaling a 6:1 MAS.

If you find this to be a bit slow going no need to worry. This is a skill that takes time to perfect. With practice and a little patience you will be proficient in no time.

Now let's take a minute and focus on the 4:1 and 5:1 block and tackle system. The 4:1 block and tackle system can easily be converted to a 5:1 by simply flipping the system around. To better explain, take a look at Figure 6 you and you will see a 4:1 MAS. Notice in a 4:1 the knot faces the anchor. If you flip the system so the knot faces the load and add a directional pulley to the anchor so you can still haul in a downward motion you have a 5:1 MAS.

When dealing with block and tackle systems if the terminal end (the knotted portion) of the rope is attached to the load the system will have an odd number. If the terminal end of the rope is attached to the anchor, the system will be an even number. As I stated earlier, figuring out the mechanical advantage of a system is a visual skill. Food for thought, if you don't have rope equipment to train on grab a pen and paper and draw some systems yourself. It's a simple way to stay sharp on a important skill.

Anchor Systems

Let's now talk about the foundation of any rope system, the anchor system. Anchors are the foundation of any rope system and your system is only as strong as your anchor. For this reason, great care should be given when choosing your anchor.

There are two categories of anchors, bombproof and pseudo. Bombproof anchors are considered to be structural members. To simplify it further think of it like this. if the structural member fails it would have a catastrophic effect on the structure itself. That's an easy way to decipher if your anchor is bombproof or not. Pseudo anchors are simply any anchors that are not bombproof. There is one rule pertaining to psuedo anchors; they must be backed up by an anchor of equal or greater strength and size.

On a safety note, get in the habit of backing up all your anchors. Doing this will only broaden your safety margins.

When constructing your anchor system always consider the direction of pull. Basically what this means is when your main line is loaded it's going to find its plumb point. Your job is to anticipate that point and keep your anchor in line with it. Granted this can not always be done. However this is not a problem. We can use something called a directional pulley. Basically a directional pulley is a means to redirect the rope in a more desired position. If we don't have an anchor in line with our main line's plumb point we can use a directional pulley to bring it to that location. Remember the anchor that your directional pulley is on should be bombproof because it will see a greater load than the main anchor is seeing.

Vehicles, preferably large ones, can be used as an anchor. However, you must chock all four tires, put the emergency break on and take the keys out of the car. When anchoring to a vehicle be sure to anchor to a structural component such as the frame.

One last anchor type to talk about is artificial anchors. Artificial anchors are special types of hardware designed for the purpose of being an anchor attachment point. This type of anchor, which includes bolts and cams, is mainly used in sport climbing. However, heavy duty steel anchor plates that can be bolted down are used in urban rope rescue.

Other Considerations

Edge protection is essential in most any anchor system. Take the time to inspect the object or objects you're utilizing for your system. Look for abrasion points or areas that will cause damage to the rope, webbing or anchor straps in your system. These areas can be simply padded out using manufactured edge protection, by placing an empty rope bag or an old section of hose over the area (see Figure 7.)

Remember when in doubt, back it up.

The third component to our mechanical advantage system is a belay system. The belay will catch the load in the event of a main line failure or any other reason causing the main line to release. Your belay should be what's called an automatic belay. What that means is the belay will activate on its own, eliminating any potential human error. Your belay system should be assigned its own separate anchor attachment point. What that means is on a bombproof anchor the belay should be connected to a separate anchor strap than that of which the main line is attached to. When dealing with questionable anchors an entirely separate anchor should be utilized to ensure safety.

A sub-category belays can be put in would be "hard" and "soft" belays. Hard belays meaning the belay is a piece of hardware such as a 540 Rescue Belay. The term soft belay would refer to a pair of tandem prusiks. Don't confuse a progress capture device (PCD) for a belay. They may look the same. However, their jobs are very different. Belay and anchor systems will be looked at more in-depth in future articles.

The last component of a MAS we will discuss is called a load releasing hitch (see Figure 8). The load releasing hitch must be used when tandem prusiks are used as the belay system. In the event, the prusiks should lock up the load, releasing hitch will allow us to transfer the load back onto the main line and in turn free the now locked prusiks. When operating with tandem prusiks it's a good idea to keep a haul system pre-built that can be connected to or "piggybacked" onto the belay line to raise the load allowing you to free the prusiks (see Figure 9).

As with any rope system, organization and good planning are the keys to success. Don't over engineer a simple operation. Keep it simple, keep it safe and keep a good perspective of the operation from start to end. Future articles will focus on anchor and belay systems.

Stay safe, stay progressive

MICHAEL R. DONAHUE is a 13-year veteran of the fire service is assigned to Rescue Company 1 in Elizabeth, NJ. Mike is the owner and founder of Progressive Rescue, a company dedicated to further firefighter's in all aspect of the job. He holds the title of rescue specialist with New Jersey's Urban Search and Rescue Team (NJ-TF1) and he is actively teaching at Middlesex and Somerset fire academies and the Middlesex County College as their Fire Science Program Coordinator. Michael has been guest on two Firehouse.com podcasts: The Buzz on Technical Rescue: Special Operations Roundtable and The Buzz on Technical Rescue: Rope Rescue Operations. View all of Michael's artices and podcasts here. You can reach Michael by e-mail at: [email protected].