Firefighters: Building Construction is Still Your Enemy

Recently, I was discussing textbooks and reference materials that I have in my library at home with some of my constituents. Spending over a quarter of a century in the fire service has allowed me to amass a considerable amount of literature as it pertains to the discharge of our duties as firefighters. There are a few that I continue to reference, primarily because these specific books have proven to withstand the passage of time, techniques and industry standards. One such book will always be Frank Brannigan’s third edition of Building Construction for the Fire Service (BCFS). While I also possess the latest version of this manual, I will go on record and state that I will never find a reason good enough to discard this reference guide, for a few reasons. First and foremost, I tip my helmet in respect to the Old Professor and Glen Corbett, PE, for combining forces prior to Frank’s passing to deliver the high-quality fourth edition of BCFS. Although I have a copy of that edition as well, I still use his third edition consistently more than any other reference book in my library. Secondly, the copy I have was signed by the Old Professor himself; it is irreplaceable.

Frank’s mantra, “The Building is Your Enemy. Know Your Enemy,” was drilled into my subconscious at an early age, and I continue to preach his words to anyone who will listen. It is a message that I continue to pass on to every one of my department members, boot school recruits, seminar attendees, and fire service professional within earshot of my discussions. In order to “…Know the Enemy” we owe it to his memory to continue to seek out new ways that the “Enemy” is plotting to catch us off-guard, laying in wait to catch us in a moment of apathy. A great way of doing this is our “field trips” to construction sites within our first-due response area, looking to see how the structures are built before the fire. Additionally, I have been known to travel with a digital camera within close proximity for just this reason; many times construction “techniques” are present, wide open for all to see. As I have done so for many years, I have photographed some interesting existing construction “concerns” that raised an eyebrow when I saw them for the first time. In keeping with Chief Brannigan’s message, I present a few “nuggets” of building construction awareness that you should feel free to pass on to anyone who wants them.

Construction Site Visits

A new residential development was being constructed within 2 miles of my station, so we took a ride over to see how the construction was progressing. Photo 1 was taken at the area where construction materials are dropped off by delivery vehicles for crews to grab as needed. A stack of TJI joists were draped over a job box, and curved and weakened as they sat. These TJI joists are used in the floors and roofs of these residences; it is bad enough that during construction, it is rare that the cutout guidelines are followed. Most of the time I have seen cutouts widened beyond the maximum limit by workers. Finding these joists in this condition is disheartening, because I know these joists will find their way into the floor of one of these new “starter castles.”

Looking inside one of the castles, I immediately was intrigued by the presence of an indoor balcony within the great room (Photo 2). Further scrutiny revealed a series of cantilevered beams that were hung in joist hangers and Tico sheer nails, and extended out from a Parallam header in the room. Furthermore, the voids within the bottom of the balcony house a number of recessed light fixtures. The voids will allow fire to travel unimpeded, and attack the cantilevered beams, possibly leading to early collapse on an unsuspecting hose team.

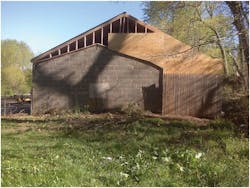

Traveling on my way to work, I drove past a garage that was being “renovated,” so to speak. What really caught my interest was the method of transformation this building experienced. Many times buildings are renovated and rarely have any problems with the end result. However, comparing Photo 3, the finished result, and Photo 4, during construction, suggest that many surprises lay in wait within this garage. The smart IC that familiarizes oneself with construction in the surrounding area can feel confident with the tactics deployed at an emergency. This one suggests a defensive posture early upon arrival.

Home Visits & Response Findings

Our crew was sent out to perform a smoke detector compliance test at a residence that was being sold in our community. While we were there, the owner asked us to assist in changing the battery within the attic detector. Entering into the attic was not through a scuttle hatch; it was through a full-size door. Apparently the owner “renovated” this space, to allow for additional storage within the attic. His plan included sawing out multiple web posts and the king post within a series of trusses in the attic space over the garage (Photo 5). Moreover, the bottom chord of this peak roof truss is now in compression, instead of tension, because of the weight of the stored materials transferred to the floor. This area can collapse even without being ravaged by flames, but most responders wouldn’t know it by looking from the exterior.

We responded to a partial collapse of a carport after a delivery truck hit the underside of the roof assembly. Upon arrival, the carport overhang was obviously displaced on the columns supporting it, but did not seem to be significant in nature. Further investigation was needed to check the interior and underside of the roof assembly, exposing a lightweight metal truss assembly within the carport (Photo 6). Responding to this facility on routine alarms usually places one apparatus within the underside of this carport; since the discovery of the staging area for apparatus has been changed.

Stopping by a construction site for a new retail store, I was curious about a truss assembly that had been placed off to the side of the site. These trusses were doubled up, constructed of wood and metal, and had engineered wood thrust blocks within the webs of the assemblies (Photo 7). I took the pictures to one of the engineers on our urban search and rescue (USAR) team, and he explained to me that these are Wood Chord, Metal Web Truss Assemblies (WCMW Truss). The WCMW truss is used in the roof assembly where there exists a significant concentrated load, perhaps a heating, ventilation and air conditioning (HVAC) unit, ventilation system assemblies, and the like. Assembling these units includes a ¾” pin through both the chord and the web ends, connecting the metal webs to the chords. The insertion of this pin leaves a little more than ½” of material above and below the pins, making for a significant weak point in the assembly.

Repairs to structures are not usually exposed for all to see; in Photo 8, repairs were made to a 5-story heavy timber structure in a neighboring community. While spreader plates are common within Type III and IV construction, symmetrical placement of these plates suggests that the building was designed to use these plates and tension-rod assemblies. The beams in place in this application are serving as a “tie-back” for this wall. This is a red flag, for any response. This area must be avoided at all costs.

Looking at Photo 9, the obvious renovations are what draw your attention. Further looking at the area in question, there are multiple types of construction/loading within this wall, along with multiple layers of outside covering and siding. These clues suggest this building has been experiencing numerous problems throughout its life span. Additionally, changes to the loading of exterior walls can have a serious impact on how the rest of the structure is supported.

Conclusion

Chief Brannigan was a proponent of pre-planning buildings within the firefighter’s response area, as this arms the Incident Commander with as much knowledge about how the building was constructed prior to the fire. I continue to seek out hazards within our response area, and share this knowledge with as many people as I can. I challenge you to do the same; take your crew out for a “field trip” and look to see what is going on around you. I will bet that you will be surprised by what you will find, especially when you go out looking for it.

Until next time, stay focused and stay safe!

LT. MICHAEL DALEY, a Firehouse.com Contributing Editor, serves with the Monroe Township Fire District No. 3 and he was recently earned the Master Fire Instructor certification from the ISFSI. He is an instructor at the Middlesex County Fire Academy where he developed rescue training curriculum and serves on New Jersey Task Force 1. He is a managing member of Fire Service Performance Concepts and a monthly columnist on Firehouse.com.

Michael Daley

MICHAEL DALEY, who is a Firehouse contributing editor, is a 37-year veteran who serves as a captain and department training officer in Monroe Township, NJ. He is a staff instructor at multiple New Jersey fire academies and is an adjunct professor in the Fire Science Program at Middlesex County College. Daley is a nationally known instructor who has presented at multiple conferences, including Firehouse Expo and Firehouse World. His education includes accreditations as a Chief Training Officer and a Fire Investigator, and he completed the Craftsman Level of education with Project Kill the Flashover. Daley is a member of the Institution of Fire Engineers and a FEMA Instructor and Rescue Officer with NJ Urban Search and Rescue Task Force 1. He operates Fire Service Performance Concepts, which is a training and research firm that delivers and develops training courses in many fire service competencies.