In this article we will continue to look at building structural systems. Last month we discussed concrete, which is one of the most basic building construction components. To review, concrete is a combination of water, cement and aggregate and has very good fire restive qualities. Some of the items we need to look for when working in a structure that uses concrete as a building component are cracking, spalling and exposed reinforcing steel.

Although concrete has an excellent fire resistive quality, it is not fireproof and will fail if exposed to high temperatures. Also remember that concrete is very strong in compression and weak in tension, which is why reinforcing steel is used. Be on the look out for excessive cracking, gaps or spalling if you are concerned about building collapse.

Steel is a material that is used in many different products from cars to piping. Many times steel is used as the main support structure of a building due to its weight and cost. Steel actually accounts for about 90 percent of the metal produced in the world because of its combination of characteristics: strength, ductility, and toughness at a relatively low cost.

Steel is an alloy of iron and carbon and produced throughout the country. The steel is cast into many different shapes and forms. In building construction you will see steel in several different thicknesses and shapes. The shape and thickness of the steel encountered is of concern to firefighters when worried about fire and building collapse at on the fireground. This article will be limited to the effects of fire on steel, and how those effects may lead to a fire induced collapse.

There are few basic steel shapes that you will see often in building construction, including: angles, channels, purlins, I-beams, open web steel bar joists, and corrugated metal decking. These are some of the most typical components building construction, but there are many more. Several different steel components can be used on any one building.

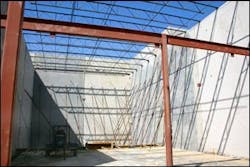

As we discussed in the previous articles, most of today's construction uses a variety of materials to complete the building. Firefighters will encounter steel framed buildings with masonry walls or lightweight metal stud walls. Crews may also encounter pre-engineered steel buildings, an affordable and quick way to create large spaces for manufacturing or storage. Regardless of what the rest of the building is made of, it is important to remember that the steel transfers its load to another bearing member somewhere in the space and at that point there is a connection.

You cannot only be concerned with the steel at the highest point, but you need to be concerned with the total building assembly. Examples of this include a horizontal I-beam attached to a vertical I-beam, a horizontal I-beam attached to masonry wall, or a vertical I-beam attached to the building foundation. It is very important to remember that the steel structure, or any steel with in the building, is just one part of the overall building assembly.

Concerns for Firefighter Safety

In the firefighting world the most important attribute of steel that you need to remember is that it is affected by heat. When steel is exposed to heat it beings to loose many of the characteristics that make it such a great building construction component, which is of major concern to firefighters in steel framed buildings. When steel is exposed to heat it will expand at a rate of around .06 to .07 percent for every 100 F of temperature rise. This is very important to remember!

The most critical fact to remember about steel is that it will fail. Steel generally starts to loose its best characteristics at about 1,000 F, as we know most of the fires we work in are in the 1,200 - 1,500 F range. Another very important concept to remember about steel is the less it weighs the quicker it will absorb heat. Therefore, a lightweight steel bar joist will fail much faster than a larger I-beam with more mass. It should be noted that when you encounter fire in a steel framed building, the steel can be kept cool by using large amounts of water, which may buy valuable time before collapse occurs.

Steel has become a very common component in building construction and in many cities, building codes do not require any fire protection for the steel members. This means that the steel is, at times, exposed to fire and elevated temperatures immediately. You need to think about the structural integrity of the building you are entering before you enter.

When you think about the steel elongating, most people often think of beams that have failed and become the twisted steel beams that you see in pictures of the remains of a fully involved structure fire. Failure of the steel beams is not the only concern you should have. Steel is often restrained by another type of material, whether it is masonry or a framed wall. If the walls are able to restrain the elongation of the steel, than one of two scenarios will take place: either the steel will remain in place, or it will twist, deform, and fail. If the walls are unable to restrain the steel you could have a complete wall collapse.

Steel is a major building component that is very susceptible to fire. Firefighters need to be prepared to deal with fires in buildings containing steel and the potential for failure of lightweight steel in less than 10 minutes. Other steel members will also fail when they have been exposed to normal fire temperatures for periods of time. This period of time will depend on the exact configuration of the steel piece and the intensity of the fire.

Steel will react to fire and will react differently depending on the exact construction of the building, which makes it important to know the buildings in your response area.

MATTHEW STIENE, a Firehouse.com Contributing Editor, is a project manger for the Mecklenburg County Real Estate Services Department, and a firefighter with Robinson Volunteer Fire and Rescue, in Charlotte, NC. He is a licensed professional engineer in North Carolina, New York and Pennsylvania, and is a certified facility management professional. To read Matthew's complete biography and his archived articles, click here. You can reach Matthew by e-mail at [email protected].