When you ask young or less experienced hazmat technicians how comfortable that they would be responding to a radiological incident, their response likely would be “not comfortable at all.” This generally comes from a lack of training, a lack of experience and a lot of misconceptions. That said, I submit that a radiation incident is one the easiest types of response. The monitors are relatively easy to use; members can protect themselves via time, distance and shielding; and the length of the incident can be predicted effectively based on half-life.

What is your role?

For most radiation incidents, a local hazmat team will be responsible for the initial response. The first priority is to establish zones. If the team has radiation detection equipment, it’s a simple process. If the team lacks the needed equipment, the U.S. Department of Transportation Emergency Response Guidebook (ERG) is a great resource. Guides 161-166 provide information for radioactive materials.

The second priority for the hazmat team to set in motion is to determine whether it is confronting an incident or an emergency.

Is it a release or an alarm failure?

Did a concerned citizen see the trefoil that’s located on a package, panic, and then dial 9-1-1?

Is a damaged container breached? Packages may have levels of radiation above background and not be breached. A correct interpretation of radioactive labels by members of the hazmat team is required to determine whether there’s a breach.

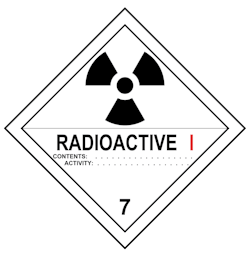

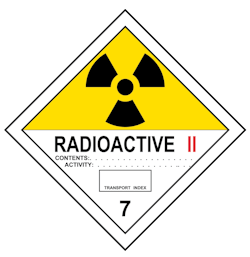

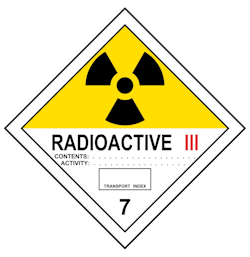

Shippers are required to measure the amount of radiation that’s emitted from a package. They then use a labeling system to indicate the level of radiation that’s emitted. These labels are classified as Radioactive I, II or III based on the amount of emitted radiation. The label will contain the name of the isotope, the level of activity and the transport index (TI). The latter is the amount of radiation that’s released from the container measured at 1 meter (3.3 feet). It’s important for hazmat teams to understand that the level of activity is shown in becquerels, and the TI is shown in millirems per hour (mrem/hr).

Radioactive White I doesn’t have a TI. The low level of radiation that’s emitted from this package isn’t detectable at 1 meter.

The labels also indicate the amount of radiation at the surface of the package.

Detection limitations

Radiation detection technology has limitations. A scene in the HBO miniseries “Chernobyl” illustrates the limitations of radiological monitors. Shortly after the explosion, a technician who is in the control room checks a wall-mounted monitor. The monitor doesn’t indicate excessively high levels of radiation. As a result, it gives the control room staff a false sense of security.

This is a factual depiction of the event at Chernobyl. The operators weren’t aware of the limitations of the monitors. However, the radiation levels were much higher than the capabilities of the monitor. There isn’t a consensus of the actual levels of radiation in the control room. That said, it’s widely accepted that staff would have reacted differently if they knew the true level of radiation.

A recent incident in Brookhaven, NY, also illustrates the need to understand the capabilities and limitations of detection and monitoring technologies. A trash hauler entered the scales at the town landfill. Radiation detectors that were installed at the scales indicated a “hot load.” This isn’t unusual. A significant number of loads that go into the landfill contain soiled materials and household trash from individuals who are undergoing medical treatments.

Per policy, the load was dumped and sorted by members of the landfill staff, who utilized handheld radiation detection equipment. The radioactive trash was segregated, and a hazmat response from the Brookhaven Division of Fire Prevention was initiated.

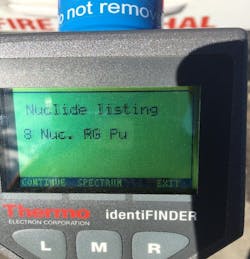

Utilizing a ThermoFisher identiFINDER, the Brookhaven Division of Fire Prevention hazmat team surveyed the segregated trash. The sodium iodide-based device indicated the presence of a nuclear class of material, reactor-grade plutonium, with a reading of 19 µrem/hr and no neutrons. Although this is a low-level reading, it’s an attention-getter. The Brookhaven hazmat team leader reached out to Brookhaven National Laboratory for assistance. This resulted in an on-scene response from the Department of Energy’s Radiological Assistance Program (RAP) team.

Knowing that the Brookhaven hazmat team used a sodium iodide-based device that produced misleading results, the RAP team used a high-purity germanium crystal (HPGe) detector and identified the isotope as lutetium-177 (Lu-177), which is a medical isotope. (Lu-177 has been used in Europe for years but is relatively new to the United States. Traditional sodium iodide-based detectors lack the spectral resolution to identify this isotope.) While it awaited the arrival of another detector that used sodium iodide and zinc sulfide crystals, a FLIR R425 identiFINDER, the RAP team used a sodium-iodide detector, and it identified the isotope as uranium. When the FLIR R425 device arrived and was employed, Lu-177 was confirmed.

Training

Response to a radiological incident can be unnerving and challenging. This usually is a result of a lack of training and a lack of operational knowledge. It’s imperative that hazmat team members receive proper training and are well versed in the capabilities and limitations of their detection equipment. The Counter Terrorism Operations Support (CTOS) Center at the Nevada National Security Sites offers several levels of radiological response training. The training is fully funded, including transportation, meals and lodging.

Our thanks to Walter E. Dunn III, Brookhaven hazmat team leader, for information about the Brookhaven, NY, incident.

PRODUCT SHOWCASE

Handheld Gas Detector

The XplorIR with Quantification Package from 908devices offers real-time detection, identification and quantification of nearly 5,000 gases and vapors in seconds. This is done without any calibration required. The device is based on Fourier transform infrared (FTIR) spectroscopy. The spectral response is linear with respect to product concentration.

Hazards Monitor

Dräger’s X-site Live area hazards monitor is built for real-time monitoring in high-risk environments, with FirstNet integration at its core to ensure priority communication across agencies. Detecting as many as seven toxic gases with a wide range of sensors—including PID, CatEx LEL, IR LEL, O2, CO2 and H2S—the device is a vital tool for firefighting, train derailments and discreet hazard detection in large arenas. The monitor features a rugged design and a 50-hour battery life.

SCBA Washer

Darley’s Circul-Air Roto-Decon SCBA Washer excels in cleaning SCBA harnesses and masks using clean water with extra filtration, to ensure thorough removal of contaminants. Features include a dedicated mode for SCBA equipment with an extended freshwater rinse and selectable boiler heating for enhanced hygiene. The unit comes with a three-year warranty.

Radiation Basics

There are two kinds of radiation: nonionizing radiation and ionizing radiation. Responders are concerned with ionizing radiation.

Ionizing radiation affects the atoms that are in living things, so it poses a health risk by damaging tissue and DNA. Ionizing radiation that’s emitted can include alpha particles, beta particles and/or gamma rays.

ALPHA PARTICLES are heavy, use up their energy over short distances and are unable to travel very far from the atom. If alpha-emitters are inhaled, swallowed or get into the body through a cut, the alpha particles can damage tissue. The ionizations that they cause are very close together: They can release all of their energy in a few cells. This results in more severe damage to cells and DNA.

BETA PARTICLES are more penetrating than alpha particles but are less damaging to living tissue and DNA, because the ionizations that they produce are spaced more widely. However, as with alpha-emitters, beta-emitters are most hazardous when they are inhaled or swallowed.

GAMMA RADIATION can penetrate skin and clothing easily. Several inches of a dense material, such as lead, or even a few feet of concrete might be required to stop them. Gamma rays can pass completely through the human body; as they pass through, they can cause ionizations that damage tissue and DNA.

Units of Measurement

Two systems are used to measure radiation: the International System of Units (metric), aka SI, and the U.S. System (customary). It’s important to understand both systems. Monitors and detectors that hazmat technicians use generally read in the U.S. system. However, shippers are required to use the SI system. It’s imperative that responders understand both systems.

Here are four of the most common units of radiation measurement (the U.S. System is listed first; the SI is in parentheses):

- Curie (becquerel): The amount of ionizing radiation that’s released by an atom or any other source.

- Roentgen (coulomb): The amount of radioactivity that passes through the environment.

- RAD (gray): The amount of radiation that’s absorbed by an object or person.

- REM (sievert): The measurement of absorbed dose that affects medical conditions in living tissues.

Radiological Incident Resources

Numerous resources are available for radiological incidents.

- Department of Energy Radiological Assistance Program (RAP)

- National Guard Civil Support Team (CST)

- Individual state health departments’ radiological response teams

- Environmental Protection Agency Radiological Emergency Response Team (RERT)

About the Author

Scott Burgess

Scott Burgess recently retired as a captain/paramedic with the Nashville, TN, Fire Department and a Clandestine Drug Lab Response instructor. Additionally, he is a Hazardous Materials instructor for the Center for Domestic Preparedness in Anniston, AL.