When firefighters receive hazmat training, they enter into a new world of strange terms and unknown hazards. They might be worried about “ethyl methyl death” or “growing a third arm from radiation.” Of course, these are fallacies, but the concern that they can prompt indicates the fears that firefighters have about the unknown threats in hazmat responses.

Through instruction and safe tactics, even new firefighters who only are trained at the awareness level can manage this unfamiliar world of chemical safety. Unfortunately, some of the most basic components of this level of training are omitted even by those who have the best of intentions.

Get me an expert!

Arriving on scene of a hazmat incident can make even the most seasoned firefighter anxious. Although firefighters have many points of reference to solve the puzzle that’s presented to them on fires, medical runs, vehicle accidents and other more common incidents, the low-frequency/high-risk hazmat incident can cause tactical decision-making to be disrupted by the challenge of hazards that are unfamiliar. Some of the unfamiliar issues that are in play with hazmat challenges include how a chemical reacts with other chemicals or heat; how the chemical expands beyond the initial release; and the unique harms from the chemical. These concepts quickly can overwhelm.

It’s important for firefighters to find someone at the incident who has knowledge of the chemical that the hazmat incident involves. True, there will be some situations where no such person is present, but, often, some type of chemical worker will be on scene. Just as firefighters are comfortable with the tools of the fireground—axes, hoses, ladders, saws—chemical workers are comfortable with their tools—chemical protective clothing, science information sheets, the dangers of the chemicals.

Sometimes, the person who is knowledgeable about the chemical is a scientist, but many other workers who are on scene can have experience with the chemical to help you to quickly learn about what and how much was/is being released. This other worker could be a safety, health and environment (SHE) manager or a facility worker. This person can provide access to the facility safety data sheets (SDS), in either a physical or digital format; spill response plans; the way that the chemical is used in the facility’s processes; and emergency shut-off valves.

The transportation incident

A frequent type of hazmat incident is the transportation incident, in particular one that occurs on roadways. Here, it’s important for the responder to speak with the driver to access the bill of lading and learn what chemical is being transported, what caused the release, what was attempted to stop the leak, the quantity of material and the shipper’s cleanup company. This information can help you to get resources to mitigate the situation more quickly, to decrease the size and scope of the incident.

Firefighters should build a rapport with chemical workers in their jurisdiction. This creates a mutual respect and makes for a better relationship should an incident occur. The world of hazardous materials simply has too much information for any one person to know it all. It requires a collaborative effort of all stakeholders to develop a sound response to a hazmat release for the safety of the responders and of the public.

Quick recognition

The NFPA 704: Standard System for the Identification of the Hazards of Materials for Emergency Response diamond placard was established in 1957 by the NFPA Sectional Committee on Classification, Labeling and Properties of Flammable Liquids. In 1961, the color-coded design was adapted formally as a national standard. Despite that, the decision to require the placard on the outside of a building for first responders falls to the local municipality. Some municipalities don’t require it out of the fear of easily identifying target buildings for criminals, arsonists and terrorists.

The diamond placard can be used as a quick indicator of the level of PPE that’s needed by responders. If the highest value that’s seen is in the Red/Flammability hazard, then the responder safely can assume that the best PPE for the incident is structural firefighting gear that includes SCBA. If a higher value is seen in another category, than other chemical protective clothing most likely is needed. However, always seek additional information about the hazards and verify your PPE selection.

Special attention should be given to information in the bottom white section space (at 6 o’clock). Responders should take a moment to examine what the special hazard is (radiation, water-reactive, oxidizer, etc.) and why it specifically is listed.

Understand your meter

Although hazmat teams can use extremely complicated and expensive equipment that detects and identifies unknown chemical, radiological and biological materials, the most common meter that’s found on fire companies, the four-gas meter, can provide a vast amount of information prior to the arrival of specialized hazmat equipment. These devices are found on most first-in fire companies.

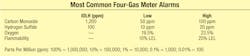

Four-gas meters typically are set up with multiple detector capabilities for departments’ most frequent gas calls. This setup typically includes the following detector components: carbon monoxide, hydrogen sulfide, oxygen and flammability.

Firefighters should be aware of these alarm levels, and action plans should be established for each of them. Most of these alarm levels are well below an immediately dangerous condition. This provides the member with an advanced warning for safety. For example, carbon monoxide (CO) is produced when incomplete combustion occurs when oxygen runs out.

Before looking at these alarm limits, it’s important to understand the unit of measure: parts per million (ppm). This is a very small measurement. To have a 100 percent level in parts per million, you must have a million parts of the chemical in the environment.

To put it in more common terms—money—if I give you $100 (the high alarm for CO in our discussion above), how close are you to being a millionaire? Not very close at all. Even if I give you the immediately dangerous to life and health (IDLH) of CO in money ($1,200), you still aren’t close to being a millionaire. This illustrates how sensitive that these meters are, so they can detect values at a very, very low concentration.

The second sensor is for hydrogen sulfide, which is a byproduct of organic decay, which frequently is found in sewers and low-lying areas. It has even lower values of concern than CO.

The third sensor, oxygen, is important in conjunction with confined-space incidents, below-grade incidents and gas leaks. Normal atmospheric conditions have about

21 percent oxygen, 78 percent nitrogen and 1 percent trace gases. Sometimes, chemical reactions can release oxygen, which produces an oxygen-rich atmosphere. Other times, the release of a gas can displace oxygen, which produces an oxygen-deficient atmosphere.

When dealing with the oxygen sensor, it’s important to look at the whole picture of the atmosphere, not just the oxygen sensor. This can give you information about another gas in the atmosphere that’s being released on a hazmat incident. When firefighters see change in the oxygen sensor, they only are seeing one-fifth of the atmosphere (remember, oxygen is only

21 percent, or approximately one-fifth, of the atmosphere). Although the oxygen sensor clearly indicates what’s happening with oxygen, it also provides information about other gases that might be released. This means that any change that’s seen in the oxygen sensor should be multiplied by five to account for the other parts of the atmosphere and the gas that’s being released that’s displacing the oxygen. This multiplication can make a low-percentage oxygen change represent a large amount of another gas in the atmosphere.

The final sensor is the flammability, or combustible gas, sensor. It detects flammable vapors. It commonly is calibrated with methane because of that gas’ affordability and ease of access. The 1:1 correlation between methane and natural gas also allows a direct reading of the atmospheric conditions that are being metered. However, for other flammable gases, a correction factor might need to be used. A correction factor is a numerical value that’s specific to the gas that’s being investigated and is provided by the meter’s manufacturer, which is multiplied by the reading on the meter.

This correction factor can move values that once were below the lower explosive limit (LEL), which originally were believed to be too lean, to a value that’s right in the middle of the explosive range, creating an explosion or flammability hazard. This is a significantly more dangerous place for responders to be regarding the fuel and oxygen mixture, with the meter giving incorrect information for the hazard present.

Similar to the other alarm limits in a four-gas meter, the flammability alarms also are below the levels of a significant threat to responders. This gives responders time to notice an alarm, address the issue and consider tactical decisions.

Solid decisions, solid outcomes

By using these considerations with hazmat responses, firefighters can make sound decisions that are rooted in good principles and practices. If an instructor doesn’t cover them during training, feel free to bring them up yourself.

Although the specter of “ethyl methyl death” still might lurk in your mind, a basic understanding of safe hazmat responses will keep you safe.

About that third arm from radiation: Although the extra appendage might be useful, it adds to the process of finding a “pair” of gloves.

About the Author

Patrick Jessee

Patrick Jessee is the commander/paramedic for the Bureau of Operations of the Chicago Fire Department, serving on the staff of the Deputy Fire Commissioner of Operations. In his 22 years with the department, he has contributed to public safety in a variety of leadership and operation-level roles, including EMS, fire suppression and rescue, and special operations (technical rescue and hazmat). Jessee also serves as the Hazardous Materials Training Program Manager for the Northeastern Illinois Public Safety Training Academy. He holds graduate degrees in public policy and administration, threat and response management, and biology as well as undergraduate degrees in biology and chemistry. Jessee is a Certified Emergency Manager with the International Association of Emergency Managers.