University of Extrication: Struts for Vehicle Rescue Applications

Topic: Factors that affect strut working load limit (WLL)

Objective: The rescue team will understand the WLL of a strut

Task: The rescue team will understand that the WLL changes with components used, strut angle, loading and strut length

Rescue teams have various strut systems. Some strut units are for lighter-duty situations and others for heavy-vehicle work, structural collapse or trench-type incidents. Vehicle-stabilization systems are designed to be placed against a side- or roof-resting vehicle and utilize an integrated tensioning strap system. For our purposes, what follows is applicable primarily to the various other types of multicomponent strut systems.

Working load limit

Manufacturers of struts publicize what commonly is referred to as ratings for their struts. These numbers are the strut’s working load limit, or WLL. The WLL is how much total load the assembled strut should be subjected to under normal rescue applications. All WLLs reflect a safety ratio, too.

To obtain the WLL, the strut is subjected to physical load tests to measure at what point it catastrophically fails. Let’s say that each time that the same model is tested, it fails at slightly more than 8,000 lbs. of load. To arrive at a WLL with a built-in 2:1 safety factor, the WLL for that strut would be established at 4,000 lbs. If you stay below the WLL, you use the tool properly and have a safety cushion built in.

A word of caution: Make sure that, while in discussions with the manufacturer, both parties are talking about the same strut capacities. You want a WLL that’s expressed with at least a 2:1 safety factor.

Say you find a strut that’s advertised as having a maximum working load of 10,000 lbs. Another system might promote that the strut was tested to a rated capacity of 10,000 lbs. The question is, “What does that number really mean?” Is it the WLL (2:1) or not? If you believe that it’s the WLL, you assume that failure occurred during testing at twice that load—thus, the 2:1 safety factor. However, it might be that 10,000 lbs. doesn’t reflect the 2:1 safety factor. In reality, it could be just an error in communication between the two parties.

Another critical issue is understanding that the WLL of a strut can vary because of components that are used with the strut, angle and length of the strut and how the strut is loaded.

Components used

This author observed a unique demonstration unit that clearly showed the influence that fixed and rigid ends can have on strut strength compared with a hinged, swivel flexible-base component. The tabletop-size demonstration unit featured two identical, blue-colored bands of thin steel that was positioned vertically in almost identical frames (see Photo 1).

Struts for vehicle rescue almost always have a hinged and, therefore, flexible base at ground level. RESQTEC offers a swivel base that has a ball-and-socket fitting for one of its strut.

Suffice it to say that flexible fittings for either end of a strut can allow for a bending movement under load conditions, which can lower the WLL of the strut.

Strut loading

Where one might refer to “centered” and “off-center” loads on a strut, the proper terms are “axial” and “eccentric,” respectively. An axial load is centered onto what this author refers to as the “spine,” or the center line, of the strut. An eccentric load isn’t evenly distributed down the spine. These additional stresses and strains can reduce the WLL, too.

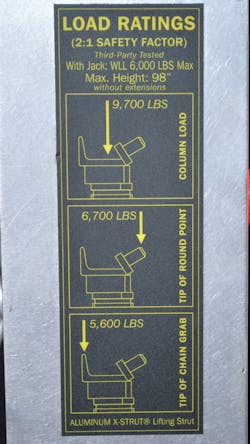

Res-Q-Jack affixes labels to its units to clearly depict the WLLs for axial/centered and eccentric/off-center loads. The company’s CRG head, like many competitors’ heads, has side protrusions, including a chain-grab feature, that easily can allow creation of eccentric loads on the strut.

Rescuers who use struts must understand the concept of distribution of loads and stresses within a strut that’s based on the angle of the strut. Fortunately, load distribution and angles can be simplified.

The best document that this author ever saw to explain the triangle trigonometry of strut use is available free from Paratech. With the complex math calculations already completed, the Strut Multiplier chart visually and clearly explains how the angle of a strut affects the distribution of loads through the entire strut system.

There are two multiplier factors for every strut angle: the axial load multiplier on the strut body and a horizontal load multiplier that indicates the forces that try to shear or slide the base along the ground. The chart also shows that, as the angle of the strut changes, the transfer of loads and stresses within the strut system change, too. You must commit to memory two angles and the corresponding strut multiplier factors: 45 degrees and 60 degrees.

Because a strut that’s used for stabilization at a vehicle rescue incident frequently is placed close to a 45-degree angle to the ground, you must know the two 45-degree angle strut multiplier factors: 1.0 and 1.41. The horizontal multiplier of 1.0 means that at a 45-degree strut angle, whatever the load that’s on the strut is at the top, a force that’s equal to that tries to shear or slide the base of the strut horizontally. Assuming a scenario in which a strut is at a 45-degree angle and is supporting a 10,000-lb. axial load, the base must resist a force of 10,000 lbs., too.

At this same angle, the strut load multiplier factor is 1.41. Stresses that are within the body of the strut are equal to the load that’s on the strut itself plus another 41 percent of the load. So, a 10,000-lb. load on a strut that’s set at a 45-degree angle results in a strut load of 14,100 lbs.

At a steeper 60-degree angle, you have a horizontal load multiplier factor of 0.58 and an axial load multiplier of 1.15. A 10,000-lb. axial load on the body of the strut would create a strut load of 11,500 lbs. The WLL of the strut hasn’t changed, but the distribution of loads and stress on the entire system does vary.

You must be able to determine whether the strut is within its WLL, whether one ratchet strap will secure the base and whether to add pickets or go with chain.

Strut length

Manufacturers of struts accept the concept that length can affect WLL, but you might have to dig deep into the fine print to get the full information (see Photo 3). WLLs decrease with long strut lengths. Memorize the WLL for their brand of system.

Ron Moore will present “Vehicle Rescue 2021 Update” and “Electric and Autonomous Vehicles” at Firehouse Expo. To register, visit firehouseexpo.com.

Examples of factors that affect the working load limit (WLL) of a strut include:

Strut components

Strut axial or eccentric loading

Strut angle

Strut length

About the Author

Ron Moore

RON MOORE, who is a Firehouse contributing editor, recently retired as a division chief with the McKinney, TX, Fire Department and now serves with Prosper, TX, Fire Rescue. He self-published the Vehicle Rescue 1-2-3 training manual and serves as the forum moderator for the extrication section of Firehouse.com . Moore can be contacted directly at [email protected].