Several events helped shape FDNY's Hazardous Materials response plan and organization. The 1995 sarin attack on the Tokyo subway system by the Aum Shinrikyo cult led to the establishment of FDNY’s chemical protective clothing (CPC) truck companies and an increase in the number of squad companies that are capable of responding to similar incidents.

In response to the Sept. 11 attacks, FDNY established a tiered-response model for hazardous materials response incidents. The department’s tiered Hazmat Response Group comprises 146 units that have varied levels of training and equipment. These units are tasked with different roles or missions at a hazmat incident.All FDNY responders are trained to the hazmat operations level in accordance with NFPA 472: Standard for Competence of Responders to Hazardous Materials/Weapons of Mass Destruction Incidents, which defines provisions and training requirements for operations-level responders who are assigned mission-specific responsibilities. It also establishes the framework for FDNY’s Hazmat Response Group. FDNY’s hazmat technicians also are trained in accordance with NFPA 472. They have dual responsibilities in the hot zone: mitigation and rescue.

In parallel to the evolution of FDNY’s hazardous materials program, these same events led to the origin and evolution of the NFPA’s development of the NFPA 1994: Standard on Protective Ensembles for First Responders to Hazardous Materials Emergencies and CBRN Terrorism Incidents. (The first edition was released in May 2001.) The vision of this standard was that a thorough risk analysis of an incident would drive the protection level that’s required for incident operations. NFPA 1994 was designed to reduce the safety and health risks that are associated with assessment, extrication, rescue, triage and treatment operations at an event that involves hazardous materials or CBRN agents. This standard bridged the gap between 100 percent vapor-tight ensembles and liquid-tight ensembles with four levels of ensembles that provide varying degrees of vapor, liquid and particulate protection.

Ensemble upgrade

Prior to 2010, FDNY equipped units of the Hazmat Response Group with two-part ensembles that met NFPA 1991: Standard on Vapor-Protective Ensembles of Hazardous Materials and CBRN Terrorism Incidents (Level A), where the flash fire-protective overlayer was required to be worn with the chemical permeation-protective base layer. These layers weren’t separable, in that each was required to meet the NFPA 1991 base standard.Unfortunately, the multilayer ensemble added to the already high metabolic heat load on the operator. This is one of the many challenges when operating in a fully encapsulating suit, particularly for rescue missions.

In addition, the physical strain that’s associated with the effort to compress or flex suit material can elevate body temperature. This heat and the humidity that’s associated with sweat becomes trapped within the garment. Elevated temperature and increased physical exertion increase the metabolic work rate, which results in an increased respiratory rate and decreased operational time. Vision can be obscured when moisture from sweat and respiration condenses on the inside of the visor.

With the 2010 CPC upgrade program, the two-layer NFPA 1991 (Level A) ensemble was replaced with two different garments to address the different missions that take place in the hot zone.

First, the Trelleborg Trellchem VPS Flash ensemble was selected as an improved NFPA 1991 (Level A) suit for mitigation missions performed by Hazmat Company 1 and Hazmat Technician II units. The department’s new NFPA 1991 (Level A) ensemble improves operations for the technician who is mitigating the incident. Mitigation missions most often are associated with direct contact with the product. The plumbing, patching and sealing work usually doesn’t require the same physical effort as rescue operations in the hot zone.

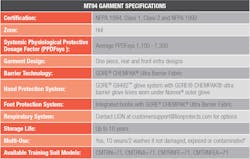

Next, the NFPA 1994 Class 1/Class 2 LION MT94 (Level A/B) ensemble was selected for rescue missions within the hot zone. Performance improvements of the LION MT94 compared with the legacy Level A garment include decreased donning time, improved visibility, a glove system that provides superior dexterity, reduction in heat stress and enhanced ruggedness. The MT94 is a nonencapsulated, gas/vapor-tight garment that is constructed from W.L. Gore’s Chempak ultra barrier fabric. The nonencapsulating design and fabric choice result in the performance improvements. Heat generation is reduced by decreasing weight and increasing flexibility of the garment.

Heat stress can be reduced even more by wetting the garment with water. The conductive cooling that takes place contributes to increased comfort. A reduction in heat stress and physical exertion results in a decrease in air consumption. As such, the responder can remain safely in the hot zone for longer periods of time.The garment’s improved ruggedness expands tactical areas of operations to include incidents that previously were considered too damaging to the NFPA 1991 (Level A) suit, including collapsed debris areas.

The MT94 is worn by the hazmat rapid-intervention team (HM R.I.T.) to respond to injured members of a mitigation team. The MT94 replaced the NFPA 1991 (Level A) for life-safety operations that require vapor-protective clothing for all units in the Hazmat Response Group. The MT94 variant in service with FDNY has attached gloves, boots and a hood that seals against the SCBA face piece via a gasket. There is no need for tape when wearing the MT94.

The MT94 also is considered a rear-entry garment, having the zipper across the shoulders of the suit. FDNY concluded that the zipper area is one of the weaker aspects of a CPC ensemble and that it is advantageous not to have the closure in the working area of the garment. There also is less chance of cross-contamination when exiting the garment post-decon when the zipper is located on the back of the garment.

The department also looked at CPC for environments that did not require high levels of gas/vapor protection. This would include decon-line operations, mitigation missions requiring liquid-splash protection and high-risk patient transport missions. FDNY worked with the garment manufacturers to incorporate the design elements of the MT94 into two new garments: a DuPont NFPA 1992 Splash garment (Level B for direct liquid splash) and an NFPA 1994 Class 3 LION ERS garment (Level C for low level vapor or liquid splash). The standardized configuration across all of these garments simplifies CPC training by having a similar don/doff procedure for all of the nonencapsulated suits.

Totally encapsulating NFPA 1991-certified garments are intended for responses that involve direct contact with pressurized liquids and pressurized vapors. For operations that fall outside of this scenario, understanding the different applicable standards and your department’s operational needs can assist in procuring appropriate CPC. Mission-specific operational standards that are within NFPA 472 can optimize your department’s capability to respond to incidents by best utilizing existing resources and setting realistic proficiency goals.

About the Authors

John Cassidy is a lieutenant and 24-year member of FDNY. He is assigned to Hazardous Materials Company 1 and is an instructor at FDNY’s Hazmat Technician School. Cassidy holds an associate degree in biomedical engineering from SUNY-Farmingdale and a bachelor’s degree in nursing from SUNY-Stony Brook.

Christina Baxter is the CEO of Emergency Response TIPS, LLC. Prior to forming her company, Baxter was the program manager of the CBRNE program at the Department of Defense's Combating Terrorism Technical Support Office. She is the chairperson for the NFPA standards for CBRNE PPE and is a committee member for several other standards in the protection and hazardous materials operations arenas. She received her doctorate from the Georgia Institute of Technology.

FDNY’s Hazmat Response Group At-a-Glance:

- Chief in charge of hazmat operations

- Hazmat Battalion

- Hazardous Materials Company 1

- 17 Hazmat Technician II Units that consist of four hazmat-technician engines, eight squad companies and five rescue companies

- 25 Hazmat Technician I SSL (SOC support ladder companies)

- 25 decon engines

- One decon support unit

- 29 chemical protective truck companies

- Five decon shower units

- 28 EMS HazTac ambulances

- 11 Rescue Medic ambulances

- Two EMS HazTac supervisors

- Three marine units

- Rescue Battalion & Safety Battalion are CPC-trained and offer additional command presence, if requested

Decon Line Operations

Decon line operations take place in the warm zone, and personnel aren’t expected to confront the concentrations that are found in the hot zone. Decon operations can be extended-duration events. For extended-duration decon events, FDNY recently procured the Lion ERS garment that’s certified to NFPA 1994: Standard on Protective Ensembles for First Responders to Hazardous Materials Emergencies and CBRN Terrorism Incidents Class 3. Warm-zone operations that have decreased threat concentrations allow for different fabrics to be used. NFPA 1994 Class 3 addresses this by having performance requirements for heat stress, by measuring total heat loss (THL) and breathability (Ret, evaporative resistance). The LION ERS uses A W.L. Gore Chempak selectively permeable fabric. The LION ERS is lighter than the MT94, and the improvements in breathability and heat loss allow the decon team to operate more comfortably for longer periods of time.

Use as a Level A

By Michael Armistead

When specifically discussing the LION MT94 suit, NFPA standards can be compared with the Occupational Safety and Health Administration (OSHA) and the U.S. Environmental Protection Agency (EPA) levels. OSHA levels were established in the 1980s by the EPA and then codified into OSHA 1910.120 for both hazardous waste-site operation and emergency response.

When we look at the levels covered, we see that only threats to skin and the respiratory system are addressed. Performance isn’t considered. NFPA standards for hazmat PPE were introduced in the early 1990s to define the minimum levels of protection and performance. Standards have evolved to keep up with the current and emerging threats. That said, this technology has limited hot-zone protection—certified to NFPA 1994: Standard on Protective Ensembles for First Responders to Hazardous Materials Emergencies and CBRN Terrorism Incidents for Class 1 and Class 2 and NFPA 1992: Standard on Liquid Splash-Protective Ensembles and Clothing for Hazardous Materials Emergencies for hot-zone operations.

What that means is that the MT94 can be used as a Level A suit in the right setting, which is another game-changer in the industry. By making entries into the hot zone in a known environment, your dexterity, vision and comfort make for more efficient response versus the heavy Level A suit. The Class 1 is by all rights considered a Level A suit by OSHA, EPA and NFPA.

About the Author

John Cassidy

John Cassidy is a lieutenant and 24-year member of FDNY. He is assigned to Hazardous Materials Company 1 and is an instructor at FDNY’s Hazmat Technician School. Cassidy holds an associate degree in biomedical engineering from SUNY-Farmingdale and a bachelor’s degree in nursing from SUNY-Stony Brook.

Christina Baxter

Christina Baxter is the CEO of Emergency Response TIPS, LLC. Prior to forming her company, Baxter was the program manager of the CBRNE program at the Department of Defense's Combating Terrorism Technical Support Office. She is the chairperson for the NFPA standards for CBRNE PPE and is a committee member for several other standards in the protection and hazardous materials operations arenas. She received her doctorate from the Georgia Institute of Technology.