Research Corner: Thermal Performance of SCBA Facepieces Exposed to Radiant Heat

Since the National Institute for Occupational Safety and Health (NIOSH) started its Fire Fighter Fatality Investigation and Prevention program in 1998, the agency has documented the conditions of the PPE and safety equipment that was involved in LODDs. It did this to determine whether the PPE or equipment contributed to the loss.

Investigations of the Cherry Road Fire in Washington, D.C. (NIOSH Report F99-21), where two firefighters died, showed that the firefighters’ SCBA facepieces were compromised by fire conditions. During another incident, which occurred during a training evolution, catastrophic failure of the SCBA facepiece likely resulted in thermal trauma, which resulted in the death of an instructor (NIOSH Report F2005-31). Further, failure of the SCBA facepiece was a contributing factor in the death of a volunteer firefighter in Maryland (NIOSH Report F2011-02). These and other investigations led to a recognition that the SCBA facepiece was the weakest link in the firefighter’s protective ensemble.

NIST thermal testing

In July 2010, representatives of the fire service and fire equipment manufacturers and researchers got together at the Emergency First Responder Respirator Thermal Characteristics Workshop to discuss how the thermal performance of the SCBA facepiece could be improved (NIST SP 1123, 2011).

As a follow-up to the workshop, the National Institute of Standards and Technology (NIST) conducted a study to quantify the level of thermal performance of the SCBA facepiece lens when it’s exposed to radiant heat fluxes between 2 kW/m2 and 15kW/m2. Facepieces were mounted to a breathing headform to represent fireground use. They were exposed to thermal loads from a natural gas-fired radiant panel. The maximum temperatures that were measured on the exterior of the lenses were approximately 290 degrees Celsius (550 degrees Fahrenheit), and the maximum airway temperatures inside of the facepiece were approximately 55 degrees C (130 degrees F) (NIST TN 1785, 2013). Under these exposure conditions, the facepiece lenses sustained various degrees of thermal damage, which ranged from no visible damage to the formation of crazing, bubbles, holes and protuberant deformations. When exposed to 15 kW/m2, the SCBA facepiece lenses reached the glass transition temperature of 140 degrees C (284 degrees F) in approximately 30 seconds, and all tested SCBA lenses developed a hole(s) in fewer than 300 seconds of exposure (NIST TN 1785, 2013).

Based on these measurements and observations, the goal was to develop an improved performance test method. Ultimately, the new test method that’s based on this research, the Lens Radiant Heat Test, was adopted in the 2013 edition of NFPA 1981: Standard on Open-Circuit Self-Contained Breathing Apparatus (SCBA) for Emergency Services.

FSRI/IFSI testing

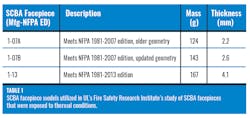

As part of a Department of Homeland Security/FEMA Assistance to Firefighters Grant (AFG) Program project, UL’s Fire Safety Research Institute (FSRI) studied several near-miss fire incidents during which SCBA facepieces were exposed to thermal conditions. To better understand the performance of current SCBA facepieces, FSRI collaborated with the Illinois Fire Service Institute (IFSI) to compare SCBA facepieces that were manufactured in compliance with the 2007 edition of NFPA 1981 with facepieces that were in compliance with the 2013 edition.

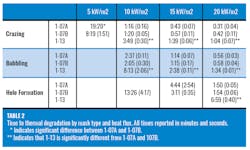

The objectives of the study were to examine the thermal degradation of SCBA facepiece lenses during single exposures to heat flux values representative of fireground conditions. New, unexposed facepiece lenses that met both the 2007 and 2013 editions of NFPA 1981 were tested. Specifically, the following two metrics were examined under various heat fluxes:

- Thermal degradation of the facepiece as characterized by time to crazing, bubbling and hole formation

- Temperature at critical locations within the SCBA facepiece

In contrast, lenses that meet the older versions of the standard developed holes at 10 kW/m2 and 15 kW/m2. Maximum temperature of the airway and of the space between the lens and headform was higher in the facepiece model that meets the 2013 edition of NFPA 1981 at higher heat fluxes. This likely was because of the extended time that the radiant load was applied. Thermal degradation didn’t reach the point of hole formation in these lenses, but there still was transfer of heat through the facepiece lens. This resulted in higher temperatures of the face and airway, which approached 130 degrees C (266 degrees F) and 100 degrees C (212 degrees F), respectively.

Improvements but limits

Although the study demonstrated that the SCBA facepieces that comply with the latest NFPA standards exhibit improved thermal performance compared with older versions, all components of the PPE ensemble have limits regarding heat transfer and thermal performance.

About the Author

Richard Kesler

Richard Kesler is a research engineer with UL’s Fire Safety Research Institute (FSRI). His research has focused on biomechanics, health and physical performance, in particular in regard to examining the physiological demands of firefighting activity and the effect of firefighting on firefighters and their equipment. Prior to joining FSRI in 2022, Kesler served as the deputy director of research programs at the Illinois Fire Service Institute. He is a member of the Savoy, IL, Fire Department, where he has served at ranks up to assistant chief. Kesler holds a Ph.D. in kinesiology and Master of Science and Bachelor of Science degrees in bioengineering from the University of Illinois Urbana-Champaign.

Dan Madrzykowski

Dan Madrzykowski is the senior director of research for the Fire Safety Research Institute (FSRI), which is part of the UL Research Institutes. He has a doctorate in fire engineering from the University of Canterbury and a master’s degree in fire protection engineering from the University of Maryland. Madrzykowski has more than 35 years of experience working to improve fire safety by conducting research and development in areas of fire dynamics, fire test methods, fire control and fire investigation. He is a member of the NFPA and serves on the committees for Fire Service Training, Structural Fire Fighting and Fire Investigation. Madrzykowski is a member of the International Fire Service Training Association's Executive Board and has collaborated with the International Association of Arson Investigators, International Association of Fire Chiefs, International Society of Fire Service Instructors and the National Fire Academy in the development of training programs. He is a Fellow with the Society of Fire Protection Engineers.