COVID-19 has become the leading cause of first responder line-of-duty deaths since the pandemic began early in 2020. Although first responders are at an increased risk for contracting COVID-19 during response calls, mitigating the risk of spread as much as possible while they are at “home” in the firehouse is vital.

Thankfully, there are measures that can be taken to improve the air quality within firehouses and to potentially reduce firefighters’ exposure to COVID-19 as well as other viruses and bacteria.

Proper ventilation and filtration in the heating, ventilation and air conditioning (HVAC) system is the first line of defense. The good news is that, after the discovery of sick building syndrome in the 1980s, the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) implemented standards for indoor air quality that mechanical engineers must follow when they design a station’s HVAC system. However, the implementation of additional methods in a station’s HVAC system provides the potential for a mechanical engineer to further improve air quality and to mitigate the risk of exposure to COVID-19.

Relative humidity

Maintaining a relative humidity (RH) between 40 percent–60 percent limits the range in which viruses and bacteria thrive. That said, if a department wants to keep a station at low RH, when designing a new station or modifying an existing HVAC system, the architectural and engineering team must be consulted.

Although ventilation is essential to providing healthy air quality, ventilating a building means that an HVAC system is less energy efficient. If fresh air constantly is brought in from outside, that air must be constantly heated or cooled to meet indoor thermal comfort levels. A balance between efficiency and air quality is required. Therefore, a building is designed for typical temperature and humidity setpoints. Without the involvement of the architectural and mechanical engineering team, there’s a risk that the system will be taxed or excess moisture will be created.

Low RH also can influence infection risk, so in certain climates or at certain times of the year, humidifier systems may be put into use to ensure that the RH level is in the 40 percent–60 percent range.

The goal of HVAC design for a fire station should be making firefighters comfortable and keeping them healthy without causing moisture damage to the building in the process of that.

Once ventilation and RH are properly maintained, filtration and purification can reduce the spread of airborne viral particles. Although research still is being conducted to determine the effectiveness on the novel COVID-19 virus, the following three methods are included in the “Core Recommendations for Reducing Airborne Infectious Aerosol Exposure” from ASHRAE’s Epidemic Task Force.

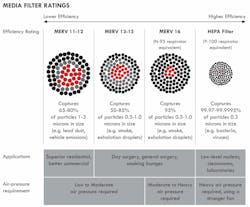

The first and most simple to understand of the three methods are media filters. These filters, such as MERV and HEPA, can be placed over return air grilles or be part of an HVAC unit. Media filters physically capture particles, such as large viruses, dander and pollen, from the air and keep them from entering a ducting system. MERV (minimum efficiency reporting value) filters come in numerous grades of filtration; the higher the MERV value, the tighter the weave of the filter and the smaller the particles that it can catch. The coronavirus is small enough that only the highest numbers of MERV filters (MERV 14 and greater) can filter it. HEPA (high efficiency particulate air) filters capture much smaller particles than do MERV filters but also further reduce the air that flows through them. Filters that are too thick for HVAC units can create a negatively pressurized space, which means that the pressure that’s inside of the room is less than that which is outside. In such a circumstance, air will be drawn in from outside. (If you ever opened the door to a room and then another one slammed close, you witnessed negative pressure. Air rushed into the room, which pulled the door on the opposite side closed.)

In a fire station, creating a negative pressure could pull contaminated air from the apparatus bays into the firefighters’ living areas.

Before popping a filter over your vents, contact an HVAC specialist to ensure that the HVAC system’s blower has the power that’s needed to push air through the MERV or HEPA filter.

Ultraviolet lights

Air cleaners that utilize ultraviolet (UV) light inactivate, rather than capture, viral, bacterial and fungal organisms. They do this by damaging their DNA. UV-C wavelength light—100–280 nanometers (nm)—provides the most germicidal effect, with 265 nm being the optimum wavelength.

These lights are placed within the air handling unit of an HVAC system and can be used to inactivate pathogens in the airstream or on a coil surface. The length of time that the air is exposed to the ultraviolet light as well as the intensity of the lamp affects the capability of the UV light to kill the pathogens on-the-fly as they pass through the irradiated zone.

Ultraviolet lights can be retrofitted to existing systems but must be replaced every 9–12 months, even if they haven’t “burned out.” The ultraviolet lights typically lose about half of their germicidal effectiveness after 9,000 hours of use.

In a congregation setting or other high-risk area, such as a day room, a training room or a treatment room, UV-C fixtures can be mounted at a height greater than seven feet to prevent direct exposure. Portable UV-C lights can be utilized for surface decontamination. However, with either of these methods, it’s important to note the dangers of direct exposure to UV-C rays. They can cause skin burns and damage eyes as well as degrade equipment or furnishings. Some ultraviolet lights produce ozone as a byproduct, which can cause throat irritation and chest pain and impair lung function. Talk to a professional before using a UV-C light.

Another type of air cleaner is bipolar ionization. The bipolar ionization system is inserted into ductwork and creates molecules that have both positive and negative ions. (To better understand how this process works, imagine rubbing a balloon to create static electricity and then watching the balloon stick to a wall.) These move through the air stream and attach to particles, pathogens and gas molecules, at sizes that are smaller than that which even a HEPA filter can catch. Once the particles start to bond, they either become too heavy to float in the air or big enough that they can be extracted from the air with a media filter.

In addition to making contaminants easier to catch in media filters, the bipolar ionization process helps to inactivate viruses, bacteria, germs, odors, etc. OH (oxygen-hydrogen) radicals form when the ions attach to the proteins that protrude from the membrane of the virus. As they divide to reproduce, the OH radicals steal life-sustaining hydrogen from the virus and return to the air as water. The destroyed proteins leave holes in the membrane, inactivating the virus on the molecular level. As a result, the air is purified, and the virus can’t infect a person even if it enters the body. This chemical reaction of bonding neutralizes the pathogens and even helps to eradicate odors, such as smoke smells, or VOCs (volatile organic compounds).

Many bipolar ionization systems can be retrofitted. A few units have sensors that show the level of contaminants, temperature and humidity that’s in the air.

As with the other purifiers, stand-alone bipolar ionization units can be used in individual rooms. However, because the bonded particles are free in the room, they are pulled to the floor or other horizontal surfaces and can then be stirred up and recirculated into the air. Some bipolar ionization products can create harmful levels of ozone. As with the other methods, ask a professional for guidance.

Access the experts

Work closely with an architect/mechanical engineer who stays up to date on the latest research. (ASHRAE’s Epidemic Task Force works to keep design professionals abreast of standards and best practices regarding COVID-19.) First responders are a department’s most valuable asset. Everything must be done to ensure their safety while on duty.

Portable HEPA Air Cleaning

A temporary and simple solution that some businesses use to improve the quality of indoor air is purchasing stand-alone HEPA filter air cleaners. These portable units, which can help to filter air in a single room, range in price from $200–$900. A large room might require more than one unit, so be sure to read the coverage area that’s recommended by the manufacturer. Also, remember that these units can be loud, so look for one that has a lower decibel rating.

About the Author

Peri Sutton

Peri Sutton is an executive associate with BRW Architects and a licensed architect who has 17 years of experience specializing in the design of firehouses. With expertise in the early stages of project development, she excels in helping clients to bring their visions to life, focusing on needs assessments, site selection, space programming and architectural design. Sutton has played a pivotal role in the development of more than 60 firehouse projects across Alabama, Michigan, Nebraska and Texas.