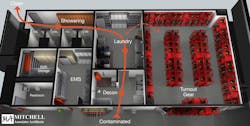

Over the past few years, the fire service has learned much about the dangers of contaminants that travel from the fire scene back to the station. Research and experience have taught us that a well-designed decontamination space in the station is essential to firefighter health and safety. The layout of the decontamination laundry can support decon protocols for the cleaning of personnel and PPE returning from the fire scene.

Some basics

Our current understanding of the health risks to firefighters and the importance of decon has much in common with the transformation of healthcare practices in the 19th century. That was a time when practitioners began to more fully understand how infections spread. Doctors who proudly wore bloodied aprons through their long days of surgery learned to change surgical gowns and to wash their hands between patients. Instruments were cleaned using newly designed sterilizing equipment. Surgical suites were modified for ease of cleaning. Incidents of infection decreased.

Today in the fire service, our understanding of the risks that are posed by exposure to toxins and carcinogens has led to new protocols at the fire scene and a significantly greater emphasis on decon at the station. Whether building a new facility or retrofitting an older station, it’s essential to understand operational needs and how to scale the decon laundry area to meet those needs. The area that’s set aside for decon can vary in size from around 500 sq. ft. to more than 1,000 sq. ft. This is determined by operations, shift size, size of staff and frequency of fires.Without careful planning, one might find oneself, for example, shoehorning in a new washer, only to find out later that it can’t be serviced (because it was wedged into a space that’s too small), that the drainage system can’t handle the flow or that wall surfaces don’t stay clean because of exposed piping or a rough finish.

For a virtual tour of a decontamination area, a laundry and a shower area of a firehouse, click here.

Decon laundry plan: area by area

Best practices of a proper decon laundry include:

The Pathway. Returning personnel should enter directly into a gross decon area, then the laundry, the showers with clean clothes lockers and the living area. The end result is entering the Cold Zone of the station clean and ready to debrief, to return to the living quarters or to return home.Location, Location, Location. It’s essential that the decon laundry is located in the Hot Zone, so there’s no need for personnel to cross into the Warm or Cold Zones for the decon process. The decon laundry must be separated physically from the apparatus bay and the administrative/living space. In addition, contaminants should be kept inside of the decon area by maintaining a negative air pressure differential via correctly designed ventilation.

The ventilation rate in the decon laundry when it’s occupied should be six air changes per hour. An occupancy sensor should be installed to determine when it’s time to turn the fan to the higher rate.

Gross decon area

The central elements of this space are metal shelving to hold contaminated PPE, a general-purpose tub sink that includes drip-dry racks and a gross decon chamber that has a high-volume hand sprayer (the kind that might be found in a commercial kitchen). A washing machine or ultrasonic cleaner for SCBA face masks, air bottles, backpacks and helmets often is included.Laundry area

Once gross decon is complete, the laundry area comes into play.

Two kinds of washers are located here: a washer/extractor that’s designed for PPE and a residential washer that can produce higher temperatures for suitable PPE and personal clothing that was at the incident scene (see “Hot Picks: Clothes Washers & Dryers”).

Because toxins from the fireground can pass through PPE and undergarments and can enter the skin of the firefighter, undergarments should be washed at the station in the decon area. They shouldn’t be washed in the living quarters nor sent home for laundering, per NFPA 1851: Standard on Selection, Care, and Maintenance of Protective Ensembles for Structural Fire Fighting and Proximity Fire Fighting.Determining the size of the washer/extractor that’s required should happen during programming before the design process of a new station begins. Be sure to consult NFPA 1851 recommendations. A washer/extractor that has a capacity of 60–65 lbs. can meet the needs of many departments, but the choice should be based on the size of staff and the numbers of calls for the department.

Individual manufacturer recommendations for capacity might vary, so ask questions and be careful not to oversize. Bigger isn’t always better. If your typical load is too small for the size of the machine, it can become unbalanced and make for extra wear and tear on seals, bearings and bushings. In the same vein, don’t undersize. A load that’s too big for the machine can decrease the effectiveness of the cleaning process.

Whenever selecting and installing any equipment, be sure to follow all manufacturers’ recommendations and to understand and follow specifications. That said, not all manufacturers publish such information. If that’s the case, demand it. Keep in mind that the more that you know, the better the questions that you can ask.

Plan for soap storage. This might seem like a minor matter, but too often, containers that feed the machine and that are stored for future use end up on the floor, which creates trip hazards and cleanup problems.

You must consider time, space and air-contamination issues that are related to gear dryers. There are two basic types of gear dryers: the externally vented cabinet and the tubular, internally vented rack. As much as 40 percent of polycyclic aromatic hydrocarbons (PAH) that can contaminate PPE on the fireground remain in the gear after washing. Rack drying can be a quick option, but contaminants that remain in the gear will vent directly into the room. A solution that’s used in some stations is to locate racks in a separate drying room that can be ventilated out of the station.

Typical time for the gear washing process is 45 minutes, but drying can require 2–3 hours. To address this time lag, install hanging racks for the gear that’s waiting for dryer time. Tubular racks in a separate room allow minimum turnaround time while not reintroducing contaminants into the air stream.Shower and locker area

Next to the effectiveness of personnel decontamination, privacy is a number one concern. The shower and locker area includes individual shower stalls that are enclosed with doors that are designed to ensure privacy. Inside of the stall, there’s a dry area for dressing. Beyond that is a curtained shower.

Nearby is a locker area where each firefighter can keep street or station clothing to bring into the shower stall for changing.

This article is part of the Station Design Supplement 2023. The entire supplement can be found here.

Installation & Maintenance Tips

Countertops and Shelving

- Should be made of stainless steel for easy cleaning

- Some should be deep enough so PPE can be laid out without falling to the floor

Surfaces

- When possible, install smooth surfaces; they are particularly easy to clean; watch out for nooks and crannies that can harbor dirt and germs

- All piping should be buried in the wall to ensure smooth, easily cleaned walls

- The ceiling is difficult to clean and often is neglected; consider a washable suspended ceiling

- Install sanitary coving at the wall and floor junction

Clearances

- Required equipment maintenance defines acceptable clearances; absolutely follow manufacturer specifications, which can vary from one to the other

- Watch room door sizes; future and potentially larger equipment might require wider door openings

Anchoring and slab requirements

- Equipment anchoring isn’t trivial; anchors must be strong enough to secure a washer/extractor that can weigh 4,500 lbs. or more and produce significant G-force during extraction; refer to manufacturers’ recommendations

- The slab under the washer/extractor must be designed specifically to handle the load

- Plumbing and drainage

- Make sure that the plumbing engineer is aware of all of the specifications before work starts

- A typical 65-lb.-capacity machine discharges approximately 25 gallons or more of water in 30 seconds at the start of extraction; drainage must accommodate that

- Laundry equipment manufacturers generally prefer trench drains; stainless steel is preferred; it should be in-slab for new construction but can be an above-slab box for renovation

Key Messages

Members of the department know its operations. Get them involved early and keep them involved through construction.

How all of the parts and pieces fit together must be understood, so the decontamination area layout and equipment support the department’s protocol, properly address health and safety, and are easy to maintain. By designing a well-thought-out and properly equipped decon area, the importance of the decon process is demonstrated to staff and the public.

Remember:

- Determine your protocol and design to it

- Evaluate the required throughput rate and number of people in the space

- Allow for ergonomics of the tasks

- Consider proposed and future equipment

- Understand manufacturers’ requirements

- Design the area so that it’s easy to clean, and keep it clean

About the Author

Robert Mitchell

Robert Mitchell is senior architect at Mitchell Associates Architects, which is teamed with Five Bugles Design as part of Wendel, which is a full-scope architecture and engineering firm. Mitchell has 30 years of experience designing fire stations and has been involved directly in more than 190 fire station and emergency services facilities projects, affecting more than 330 fire stations. More than 40 of his stations were recognized in national fire service magazines; seven won national gold prizes. Mitchell recently developed the “basis of design” for future fire stations for Philadelphia that addressed new stations and renovations, dealing directly with firefighter safety and health and decontamination. He is the author of the chapter on fire station renovation and additions for the "Fire Station Design Handbook," which was published by the International Association of Fire Chiefs Foundation, and his design ideas for incorporating training features into fire stations are featured in the "FEMA Fire Station Design Manual." Mitchell is licensed in nine states and is certified with the National Council of Architectural Boards.